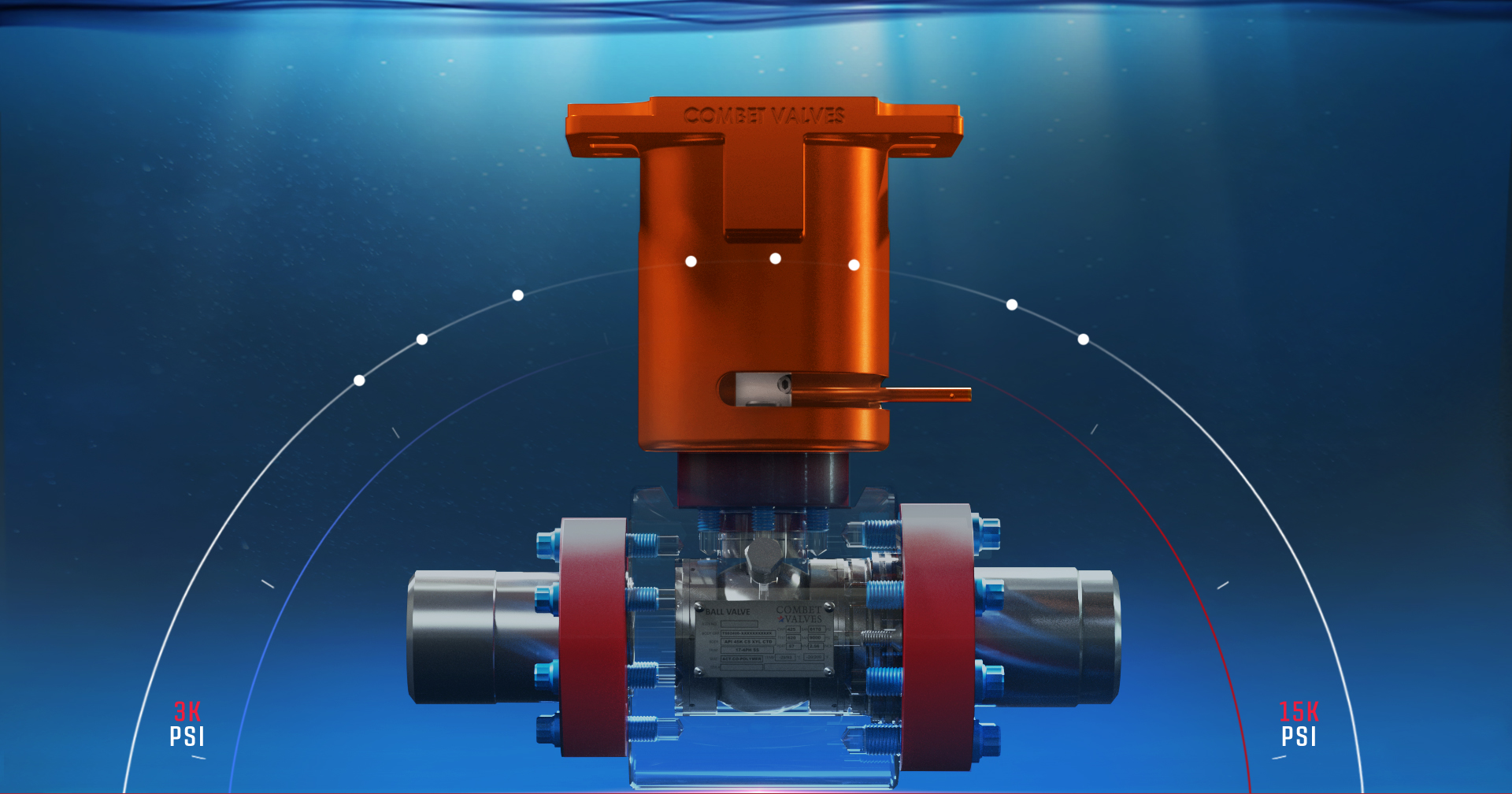

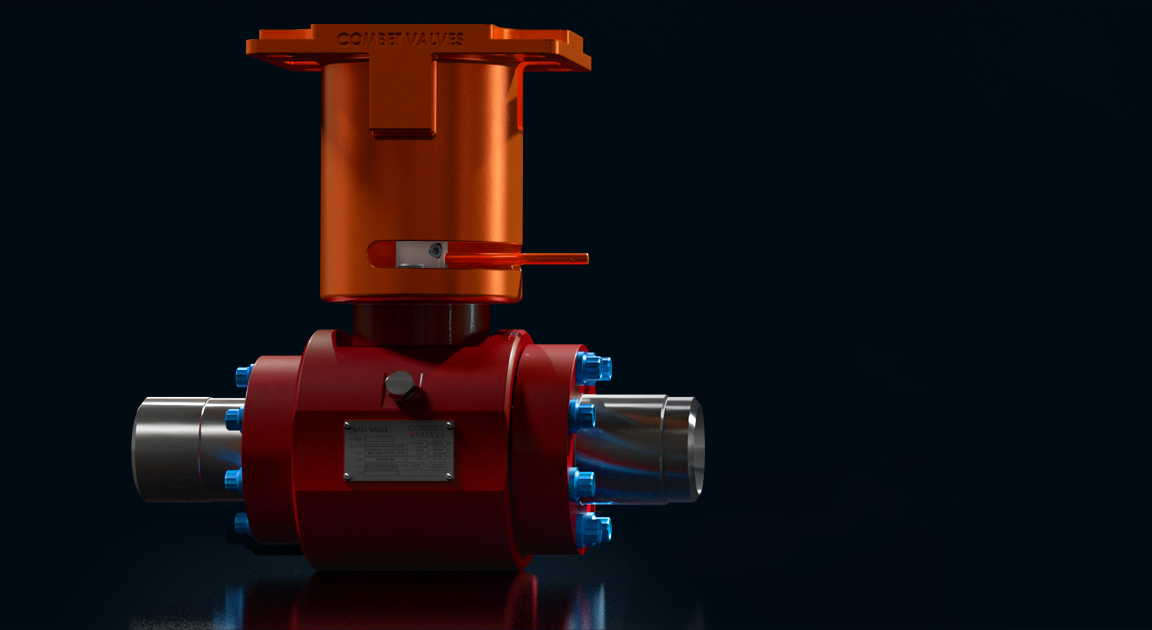

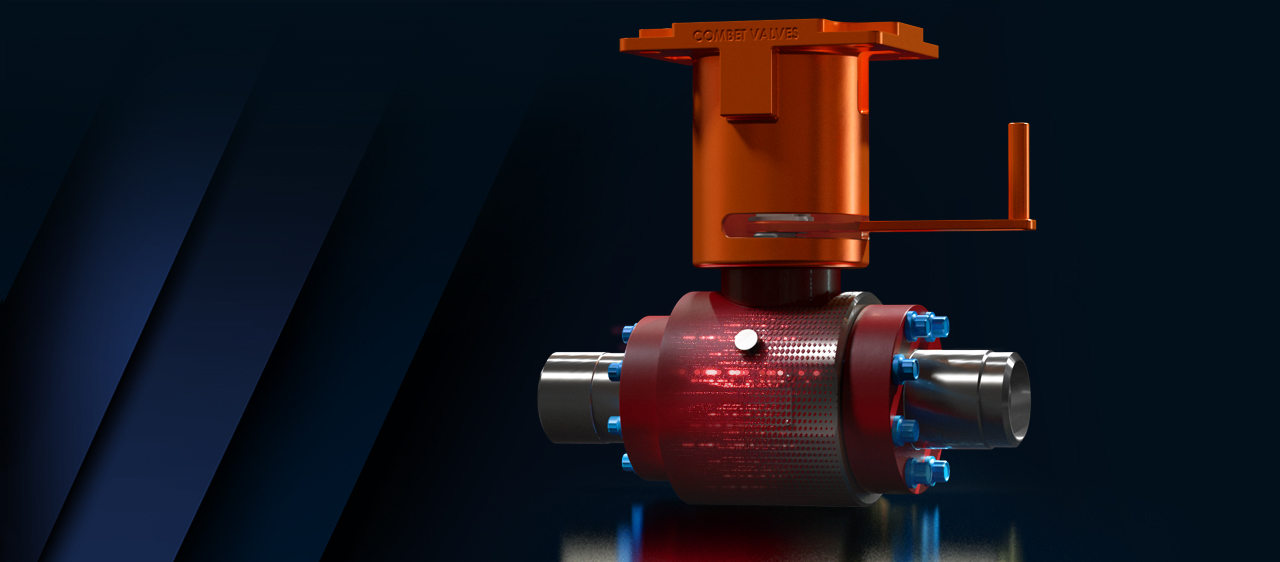

SubSea valve

I AM INTERESTED IN SUBSEA VALVE

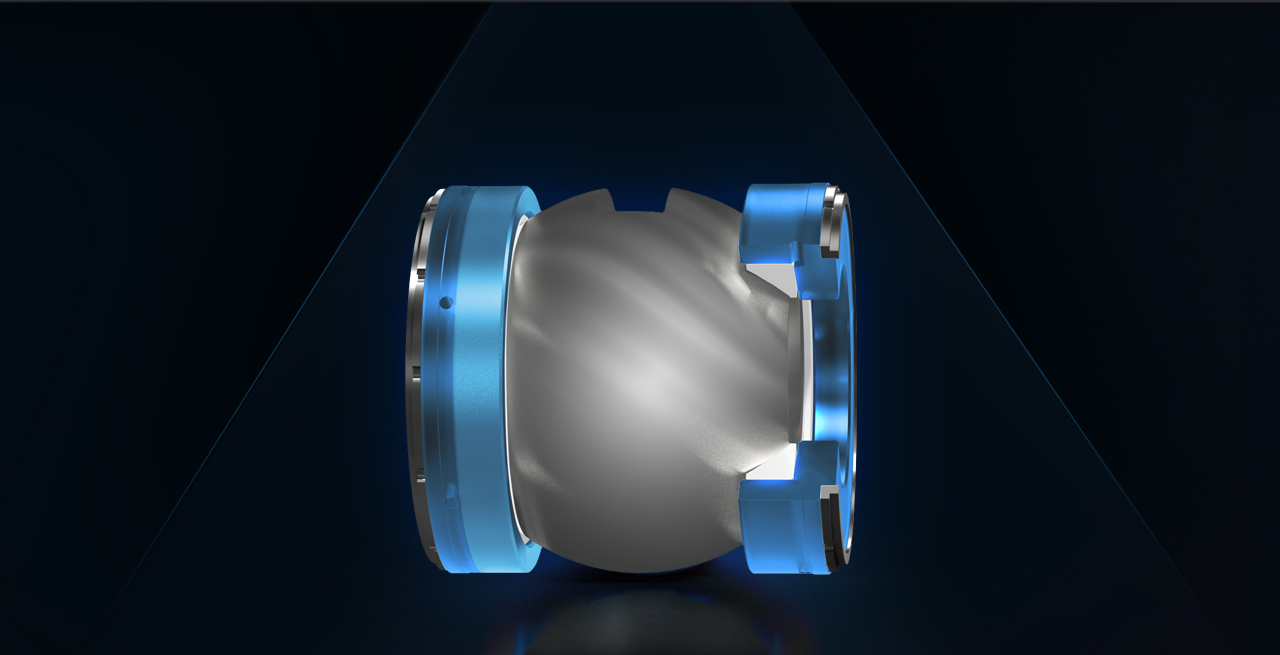

solid forged bar body

26% Higher tensile strength

37% Higher fatigue strength

And produces less waste than a casted product.

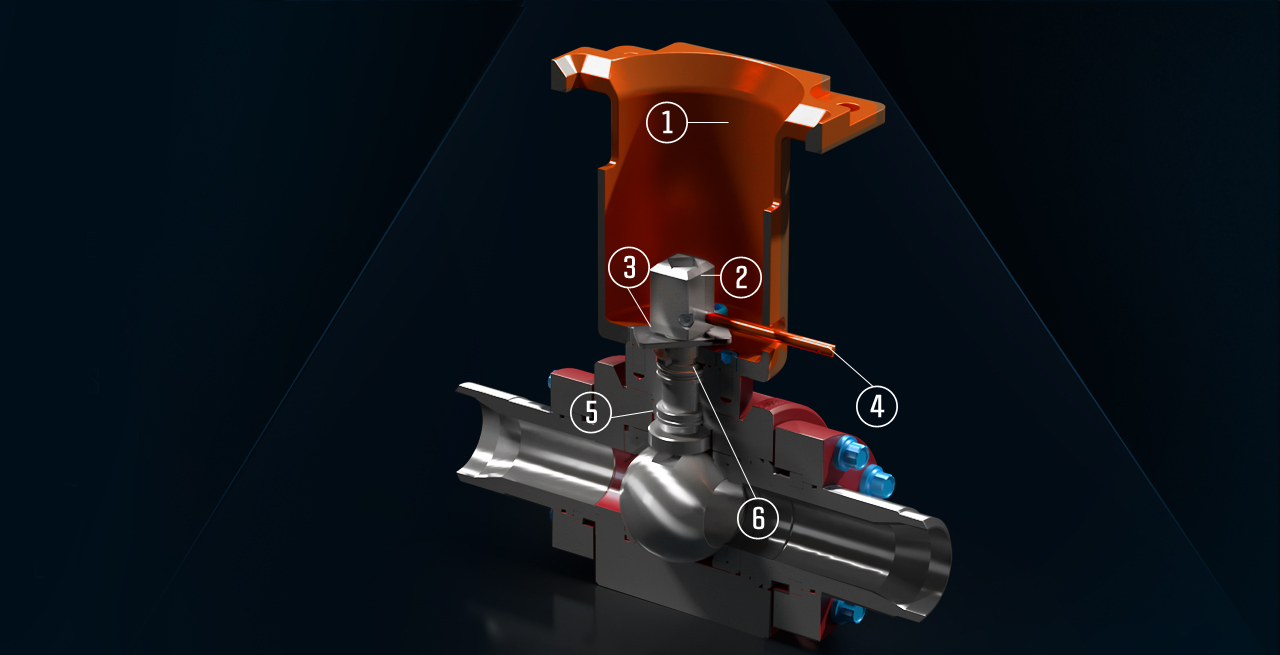

Whitford Xylan coating

Valve completely internal and external xylan coated which can extend the life by twice that of traditional valve paints.

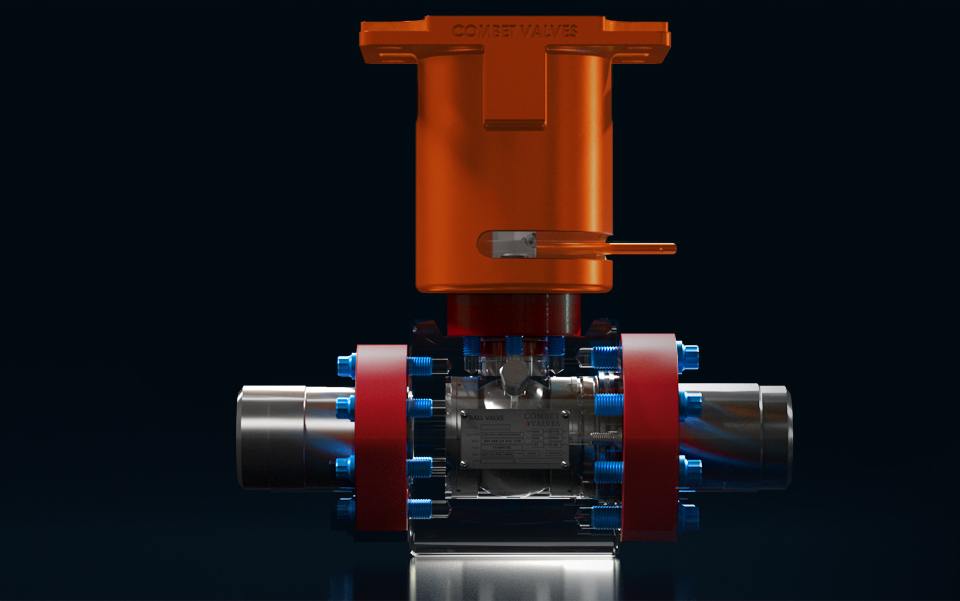

Metal-to-metal sealing system

Primary Metal-To-Metal sealing makes Firesafe Design inherent.

Elastomer O-rings are captured in the o-ring grooves in the Bonnet, Retainer and both sides of the valve.

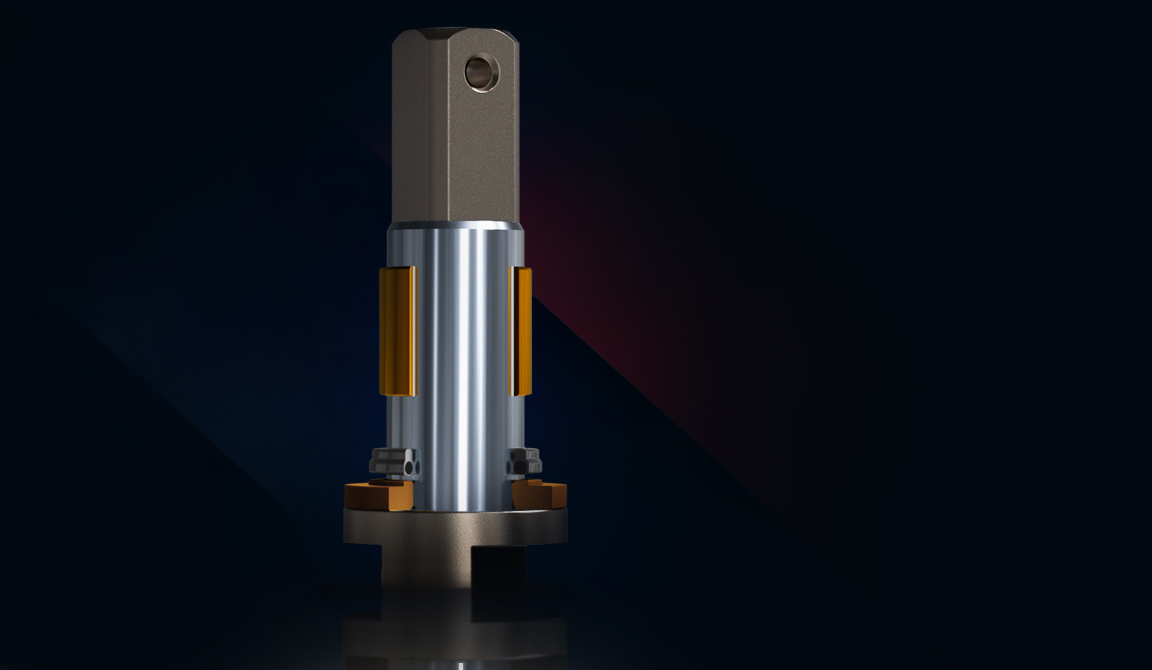

Self lubricating Bonnet

Sleeve bearing requires no maintenance.

Thrust Bearing with a machined shoulder to act as an axial bearing against the bonnet to prevent the stem from cantilevering during operation.

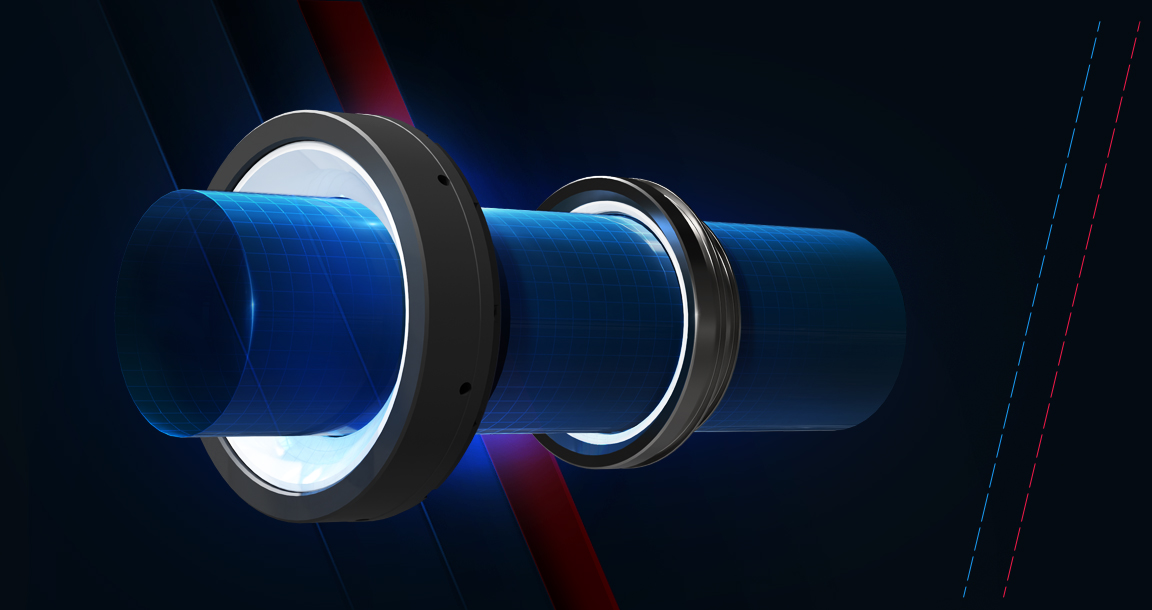

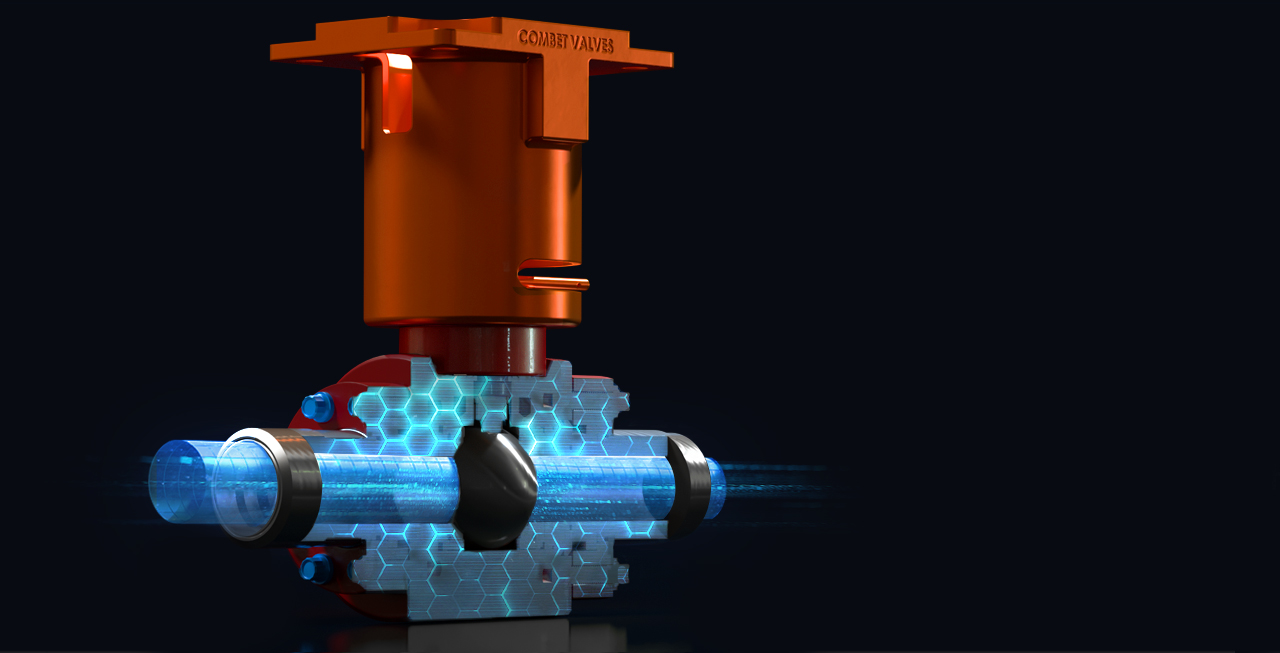

cross section 5x larger

Combet floating ball valve seat design

is up to 5X larger than competing trunnion designs.

Up to 50% reduction

in the size of an API 6D valve

Up to 40% weight

of an API 6D ball valve

combet floating

ball valve seat design

Large Ball to Seat interface to evenly distribute torque and to tolerate unprocessed produced fluid media.

Valve bore sizes

are designed to closely match standard pipe schedules specified by ASME to optimize the valve flow coefficient

L-Seal design

allows pressure to pass from the upstream side of the valve and seal bubble-tight on the downstream side of the valve.

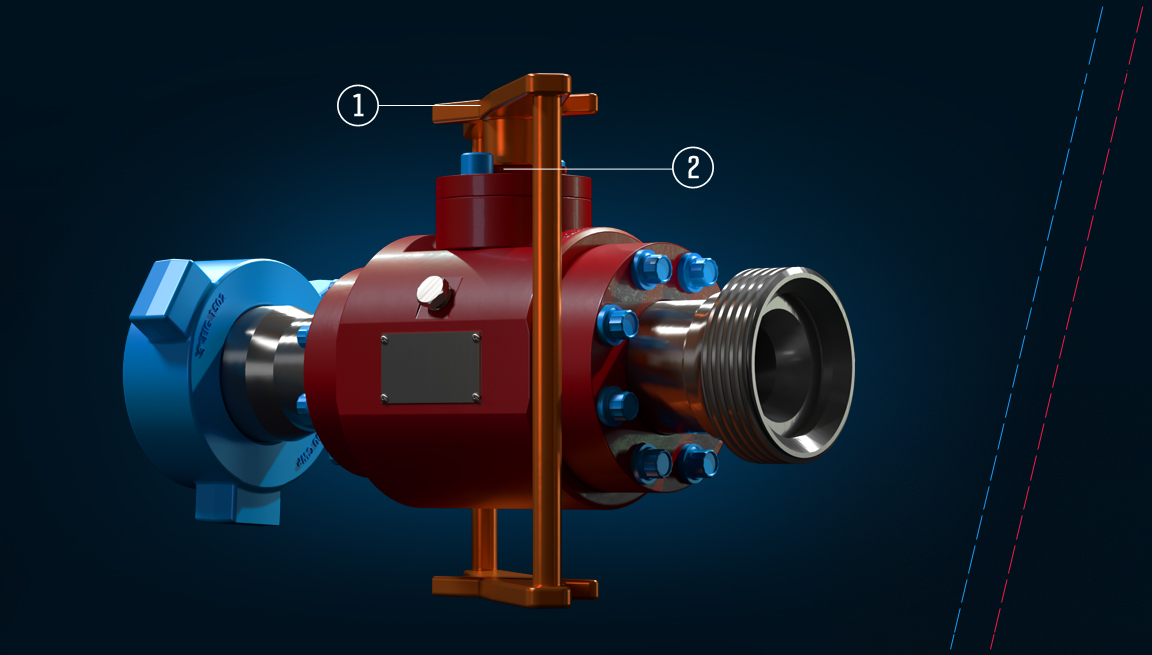

API 17D/ISO 13628-8 ROV BUCKET

- API 17D CLASS 4 ROV TORQUE RECEPTACLE

- 1-1/2” sQ DRIVE

- MECHANICAL POSITION STOP ENSURES FULLY-OPEN AND FULLY-CLOSED POSITIONS

- POSITION INDICATOR

- THRUST BEARING TO REDUCE STEM TORQUE

- SECONDARY STEM LIP SEAL PREVENTS EXTERNAL WATER ENTERING THE VALVE

ROCK BAR DESIGN

- OPEN/CLOSE POSITION INDICATOR

- MECHANICAL POSITION STOP

ENSURES FULLY-OPEN AND CLOSE

Quote request

HEADQUARTER / FACTORY:

COMBET VALVES BV

Bergveste 26

3992 DE Houten

The Netherlands

Tel. +31 (0)30-2006851

Email: info@combet-valves.com

HOUSTON STOCKING SALES REP.:

TWC the Valve Co.

Tel. (281) 566 1200